Automotive Connectors: The Critical Joints in EV and ICE Wiring

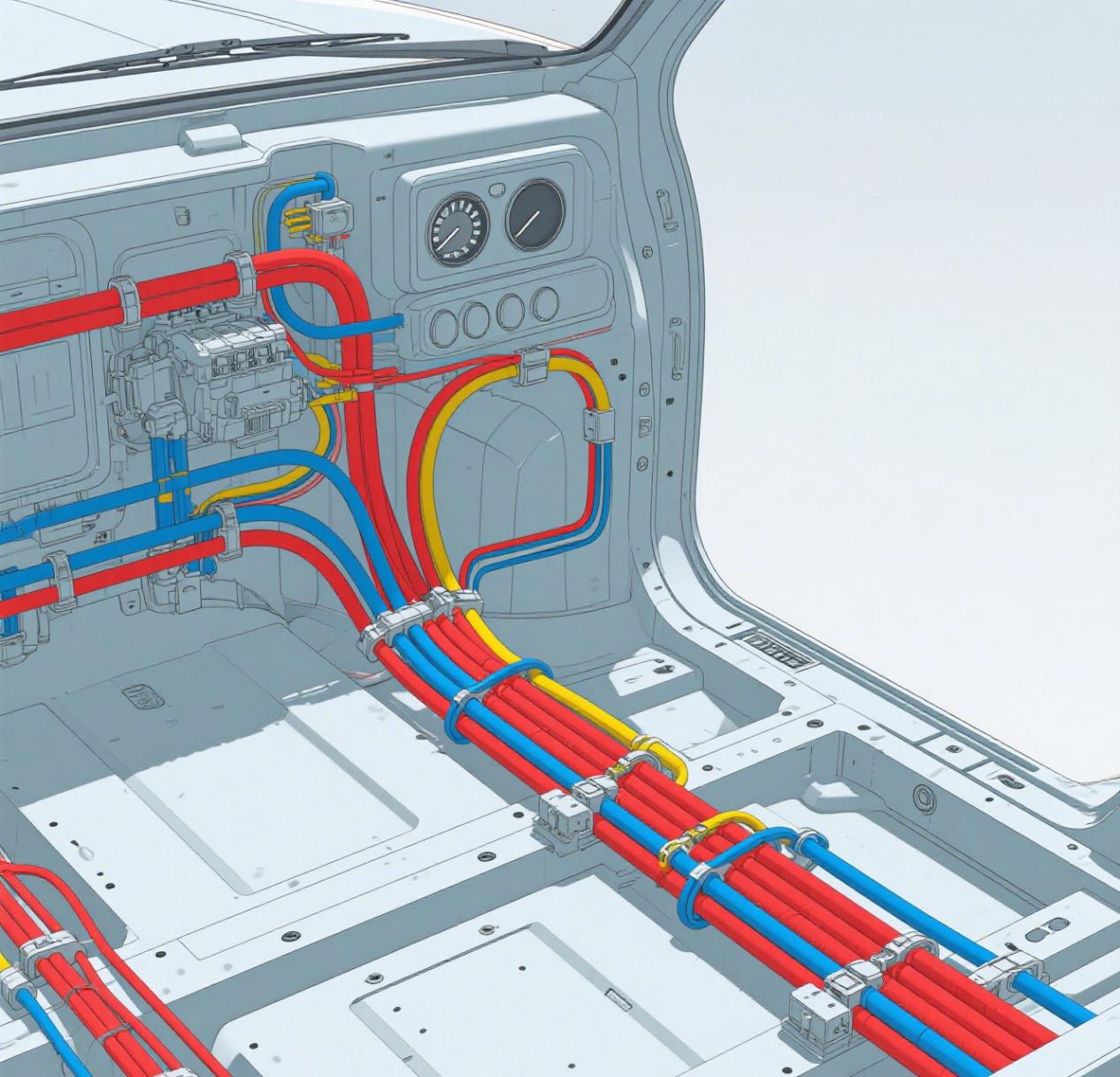

Automotive connectors are essential components that transmit electrical current or optical signals between electronic devices. Often referred to as the “joints” of a vehicle’s electrical architecture, they play a critical role across all automotive systems.

From the powertrain, safety, and steering systems to infotainment, navigation, and instrumentation—and now the increasingly advanced autonomous driving and smart cockpit features—connectors enable seamless communication and energy flow.

Without them, reliable interaction between devices, components, and subsystems would be impossible, compromising performance, signal integrity, and system efficiency.

What is a Connector?

An automotive connector is an electromechanical component that ensures the transmission of power and signals between systems within a vehicle. It operates through the conductive properties of its contact pairs, enabling the proper functioning of various components.

A typical connector consists of contacts (terminals), insulators, housings, and supporting accessories. To perform reliably in demanding automotive environments, it must meet stringent requirements such as resistance to vibration, high temperatures, moisture, and dust.

A “Bridge” to Ensure Stable Operation of Automotive Systems

Power transmission

To power car batteries, motors, lights, air conditioners and other equipment, for example, the high-voltage connectors of new energy vehicles need to carry hundreds of volts and large currents (such as fast-charging connectors that can transmit more than 300A).

Signal Transmission

Transmit sensor signals, control commands, etc. (such as signal transmission of vehicle-mounted cameras and radars), support functions such as autonomous driving and vehicle networking, and require low latency and anti-interference (such as high-speed connectors that meet USB, Ethernet and other protocols).

Mechanical connection and protection

Secure components while preventing dust and moisture intrusion, short circuits or signal attenuation through sealing designs (such as IP67/IP6K9K protection levels).

Classification by application scenario and technical characteristics

1. Classification by usage scenario and voltage level

High-voltage connector: DC 60V~1500V (mainly new energy vehicles), Battery packs, motor controllers, charging pile interfaces, etc. High-voltage, high-current, arc-proof, shielded design.

Low-voltage connector: DC 12V~48V (traditional fuel vehicles and new energy vehicle auxiliary systems) Headlights, instrument panels, door controls, sensors, etc. Low-cost, miniaturisation, and high plug-in life.

High-speed connector: signal transmission rate > 1Gbp.s On-board cameras, radars, entertainment systems, autonomous driving domain controllers Low loss, anti-electromagnetic interference, impedance matching.

2. Classification by structure and function

Board-to-board connector: connects circuit boards to circuit boards (such as vehicle computer motherboards and daughter boards).

Wire-to-board connector: connects cables to circuit boards (such as sensor harnesses and ECU electronic control units).

Wire-to-wire connector: connects cables to cables (such as segmented connections of automotive wiring harnesses).

Waterproof connector: used in humid environments such as chassis and engine compartments, and must meet waterproof levels such as IP6K9K.

3. By vehicle type and technology trend

Traditional fuel vehicle connectors: mainly low-voltage, with a quantity of about 300-500 per vehicle, focusing on cost and reliability.

New energy vehicle connectors: New high-voltage and high-speed connectors are added, with the quantity increased to 600-1000 per vehicle, and the value is significantly higher than traditional connectors (for example, the unit price of high-voltage connectors can reach 5-10 times that of low-voltage products).

Application Scenario

New energy three-electric system

- Battery: connects the battery module and the management system (BMS) to transmit power and data.

- Motor: high-voltage connection between the drive motor and the controller.

- Electric control: internal and external signal transmission of the electronic control unit.

Intelligent driving and networking

- Autonomous driving: high-speed signal transmission of lidar, millimetre-wave radar, and cameras (such as Fakra connectors for radio frequency signals).

- Internet of Vehicles: high-speed data transmission of on-board communication modules (5G, WiFi).

Traditional automotive systems

- Body electronics: low voltage connections for window, door, and seat controls.

- Lighting system: power and signal connections for headlights and taillights.

- Engine compartment: connections between sensors (such as oil temperature and oil pressure sensors) and the ECU.

The Future of Automotive Connectors

Technical barriers

Environmental Adaptability: Automotive connectors must withstand harsh operating conditions, including temperature cycles ranging from -40°C to 125°C, vibration tests (e.g., ISO 16750), and salt spray testing to simulate coastal or winter de-icing environments.

Customization Requirements: Connector specifications can vary significantly across automakers and vehicle models. Designs must be tailored to fit each vehicle’s unique electrical architecture and spatial constraints.

Certification Standards: Connectors must meet the IATF 16949 automotive quality management system certification. High-voltage connectors, in particular, must also comply with additional standards such as ISO 6469, which governs electric vehicle safety.

Market Trends

New Energy Vehicles Drive Market Growth: The global automotive connector market is projected to surpass USD 15 billion by 2025, with new energy vehicles (NEVs) accounting for the bulk of this expansion. In China alone, the NEV connector market is growing at an annual rate exceeding 20%.

High-Frequency, High-Speed Demand: The rise of Level 3 and higher autonomous driving technologies has significantly increased the need for high-speed connectors, such as HDMI and Ethernet, to support large data transmission.

Integration and Miniaturisation: Space-saving solutions are becoming essential. For instance, “all-in-one” connectors combine power and signal transmission in a single unit—Tesla’s Model 3 central armrest box is a prime example, integrating multiple interfaces into one compact connector.

Conclusion

Although often viewed as small components, automotive connectors are the foundation of vehicle electrification and intelligent systems. As new energy vehicles gain market share and autonomous driving technology advances, demand for connectors will continue to grow, both in size and in technical complexity—making it a critical and rapidly growing area in the automotive parts industry.

--- END ---

LATEST NEWS