The error-proof design of the assembly process card of the automobile wiring harness assembly line should follow the following principles:

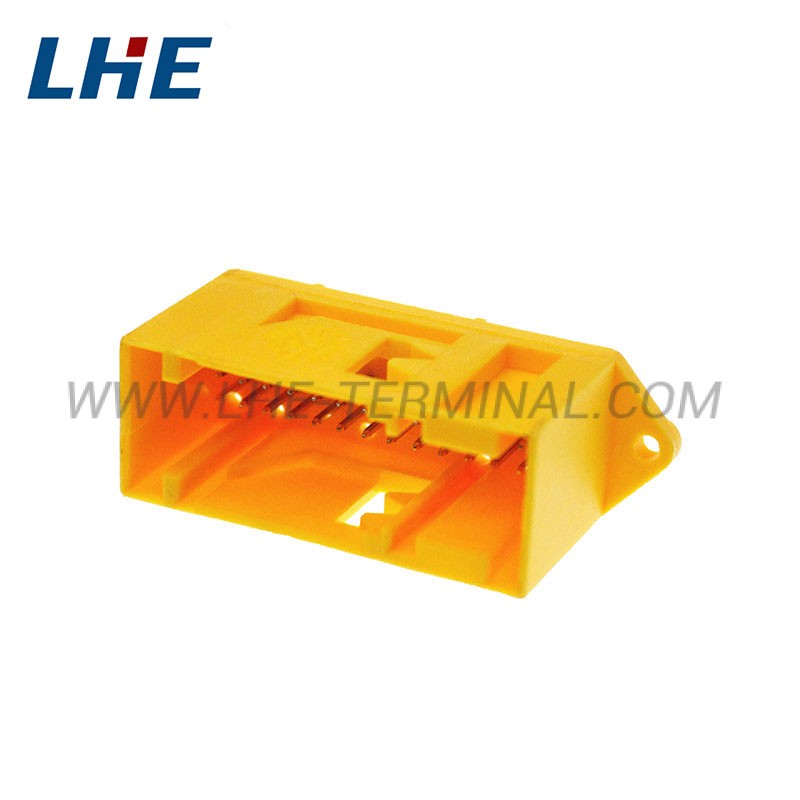

● The wiring sequence of the pre-assembled semi-finished products on the assembly board should firstly lay out the fuse box, the ECU, and the main sheath with more holes, which needs to be threaded on the assembly line. The semi-finished branch sheath of the terminal;

●The wiring of the sheath on the wiring board should be balanced, the wiring personnel can work together on both ends of the assembly board, and the working time of each hanging station to wear the terminal and buckle self-locking should be balanced;

●Installation The operation of wire harness sheath self-locking, buckle self-locking, and sheath sheathing should be indicated on the assembly line process card, and the operation should be completed by the hanging and threading personnel;

● The work scope of the dressing personnel should be in one area as much as possible, and the same tape dressing should be arranged as much as possible. regional branches to reduce the frequency of tape replacement. The sequence of operations should be branched first, followed by the trunk, and concentrated at the end to avoid cross-operation; Avoid wrong installations.