Automotive Seals Explained: Types, Functions, and Applications

Sealing systems play a critical role in the functionality, efficiency, and safety of modern vehicles. From preventing fluid leaks to protecting electronic components, automotive seals are small components that make a big difference.

In this blog, we’ll explore what automotive seals are, the various types, their materials, functions, and common applications, along with insights into choosing the right sealing solutions for optimal performance.

The Basics of Automotive Sealing

In automotive engineering, sealing refers to the use of materials and components that prevent the passage of fluids, gases, and contaminants between mechanical parts.

Effective seals help ensure:

- Fluid containment (oil, coolant, fuel)

- Noise and vibration reduction

- Environmental protection (dirt, moisture, heat)

- Mechanical integrity between moving or static components

Without proper seals, critical vehicle systems like engines, transmissions, suspension, and electronics would be prone to breakdown, inefficiency, or failure. As such, seals are vital not only for performance but also for safety and regulatory compliance.

Materials for Automotive Seals

Automotive seals are exposed to a wide range of operating conditions—extreme temperatures, high pressure, vibration, chemicals, and environmental factors. To meet these challenges, seals are manufactured using durable, flexible, and chemically resistant materials such as:

- EPDM (Ethylene Propylene Diene Monomer): Excellent resistance to heat, ozone, and weather, commonly used in weather seals and brake systems.

- Nitrile Rubber (NBR): Good resistance to oil and fuel, making it suitable for fuel system seals.

- Silicone Rubber: Withstands high temperatures and UV exposure, used for electrical insulation and under-the-hood applications.

- Fluoroelastomer (FKM/Viton): High-performance elastomer with resistance to heat, fuel, and oil, ideal for high-stress sealing environments.

- Thermoplastic Elastomers (TPE): Combine flexibility and durability, often used in gaskets and custom-moulded parts.

The choice of material depends on the seal’s intended function, exposure conditions, and durability requirements.

Different Types of Automotive Seals

Automotive gasket and seal manufacturers produce a variety of rubber seals to serve different functions across vehicle systems. Below are some common types of seals and their roles

Rubber Washers

Rubber washers are flat, ring-shaped components with an open center that allows fluid or mechanical parts to pass through.

- Provide cushioning and insulation

- Prevent fluid leaks at pipe or hose junctions

- Absorb vibration and reduce wear between metal parts

- Help isolate electrical components from conductive materials

Rubber washers are essential for fuel systems, cooling systems, and anywhere a secure, low-abrasion seal is needed.

Rubber Gaskets

Rubber gaskets are one of the most widely used sealing solutions in the automotive industry. They are cut from sheets of rubber and customised into specific shapes and thicknesses to fit.

- Engine components (valve covers, oil pans)

- Transmission systems

- Exhaust systems

- HVAC systems

Their ability to withstand heat, pressure, and chemical exposure makes them ideal for static seals between non-moving parts. Rubber gaskets are also known for their affordability and versatility.

Rubber Bushings

Rubber bushings act as isolators and cushions between moving parts. They are typically cylindrical components used in:

- Suspension systems

- Engine mounts

- Gear sticks

- Steering assemblies

Bushings reduce noise, absorb road shock, and eliminate metal-to-metal contact, enhancing ride comfort and component lifespan. They also reduce the need for lubrication in areas with relative motion.

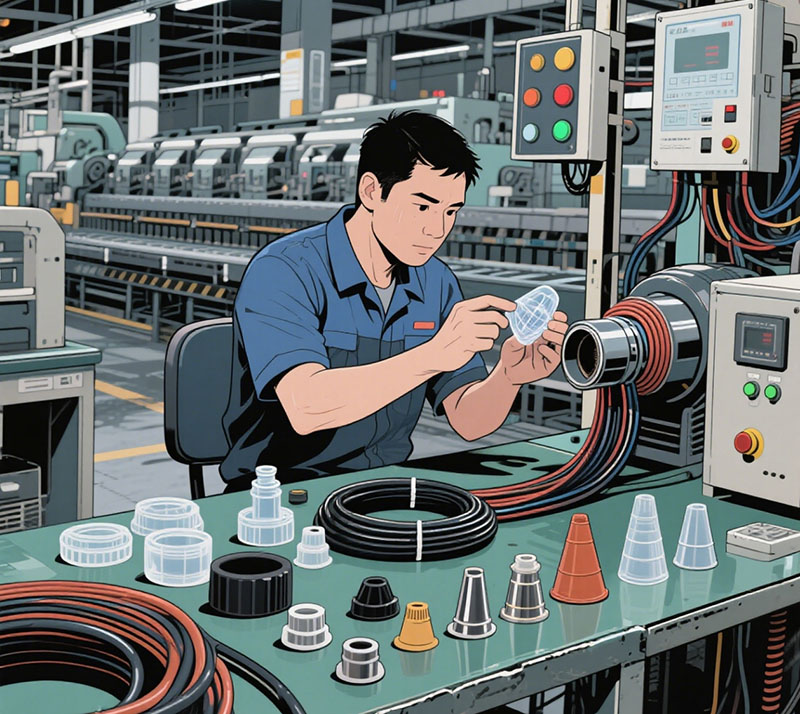

Silicone Rubber Tubing

![]()

Silicone tubing is a highly versatile sealing solution due to below reasons.

- Excellent temperature tolerance (up to 200°C and beyond)

- UV and ozone resistance

- Electrical insulating properties

- It is commonly used for:

- Electrical cable and wire insulation

- Vacuum lines

- Coolant and heater hoses

- Turbocharger systems

Silicone tubing is especially popular in high-performance and racing vehicles where thermal and mechanical stresses are elevated.

Functions of Automotive Seals

Automotive seals perform a wide variety of functions that go far beyond simple leak prevention.

Their roles include:

- Sealing Fluids and Gases: Preventing oil, fuel, coolant, or air from leaking in or out of various systems.

- Reducing Noise and Vibration: By acting as insulators and shock absorbers.

- Environmental Protection: Shielding internal vehicle components from dust, water, road debris, and contaminants.

- Mechanical Isolation: Preventing metal-on-metal contact and extending the life of parts.

- Maintaining Pressure and Performance: Essential for systems like brakes, power steering, and HVAC, where pressure differentials matter.

Whether static or dynamic, automotive seals are designed to perform consistently over long periods and under harsh conditions.

Applications of Rubber Seals in the Automotive Industry

Automotive rubber products play an important role in many applications in the automotive industry. Their main uses in mechanical equipment include filling gaps between components, minimizing damage caused by vibration, preventing leakage of liquids or gases, and blocking contamination from moisture or dust.

However, different applications require different types of protection. Now that we understand the differences between different types of automotive rubber solutions, let’s look at some of the applications where they are used below applications.

- Engines: Gaskets, valve seals, O-rings, and timing cover seals

- Transmissions: Shaft seals, gaskets, and bushings

- Suspension Systems: Control arm bushings, shock absorber mounts

- Electrical Systems: Silicone tubing and grommets for wire insulation

- Cooling and HVAC Systems: Radiator hose seals, heater core gaskets

- Braking Systems: Calliper and master cylinder seals

Additionally, weatherstripping and door seals improve vehicle aerodynamics and passenger comfort by blocking wind, noise, and rain.

Selecting the Right Sealing Solutions

The exploration of automotive sealing technology highlights its integral role in achieving and maintaining optimal vehicle fuel efficiency. Through strategic material selection and innovative design, sealing solutions can minimize energy loss, reduce emissions, and improve overall vehicle performance.

Selecting the right seal is not only about fit, but also about performance, reliability, and compatibility.

Key factors to consider when selecting a sealing solution include:

- Application requirements: pressure, temperature, and chemical corrosion

- Material compatibility: resistance to the relevant fluids and gases

- Durability expectations: how long the seal needs to last

- Customisation needs: shape, size, and specific vehicle design

For original equipment manufacturers (OEMs) and aftermarket manufacturers, working with a trusted sealing partner ensures access to high-quality materials, stable production, and technical support. For newer models or high-performance applications, custom moulded solutions are often necessary when off-the-shelf parts are not enough.

As automotive technology advances, especially in electric and hybrid vehicles, the demand for precision-engineered seals continues to grow. From thermal management of electric vehicle batteries to fluid sealing of autonomous vehicle sensors, the sealing industry is adapting quickly to meet emerging needs.

Conclusion

Automotive seals may not be the most visible part of your vehicle, but their impact cannot be ignored. These small yet powerful components protect systems, ensure performance, and extend the life of everything from engines to electronics.

Understanding the types, materials, and functions of automotive seals is critical. Whether you’re sealing a gasket in a classic V8 engine or installing a silicone hose in a high-tech electric car, the right sealing solution is critical.

When performance, safety, and efficiency are critical, choosing the right automotive seal is more than a detail—it’s a necessity.

--- END ---

LATEST NEWS